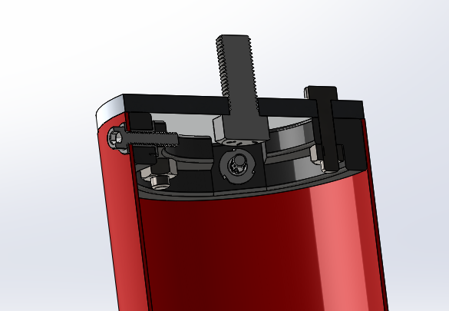

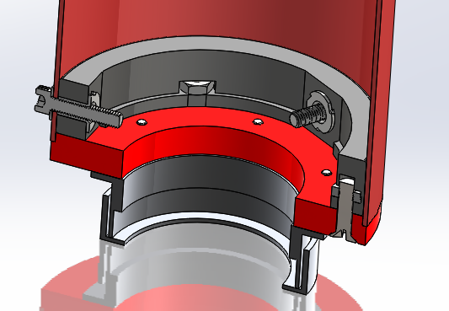

Rocket Motor Adapter

I designed and built a motor adapter to test 54 mm rocket engines, a standard size in amateur rocketry. The adapter was engineered to balance strength and weight by combining lightweight composite materials, 3D-printed components, and precision-machined metallic parts. This hybrid approach allowed for both structural reliability under high loads and ease of fabrication, making the adapter versatile for repeated use in engine testing. The design proved successful, having been used in two separate static fire tests with consistent performance.

My roles

Used SOLIDWORKS to design rocket motor adapter to integrate standard size rockets onto test stand

Used in two successful static fire tests of solid propellant motors

Utilized 3D printed and composite materials for lightweight forms of strength

Machined metallic components on manual mill

Used hand tools for final assembly of motor adapter