Hybrid Rocket Engine @ VCU

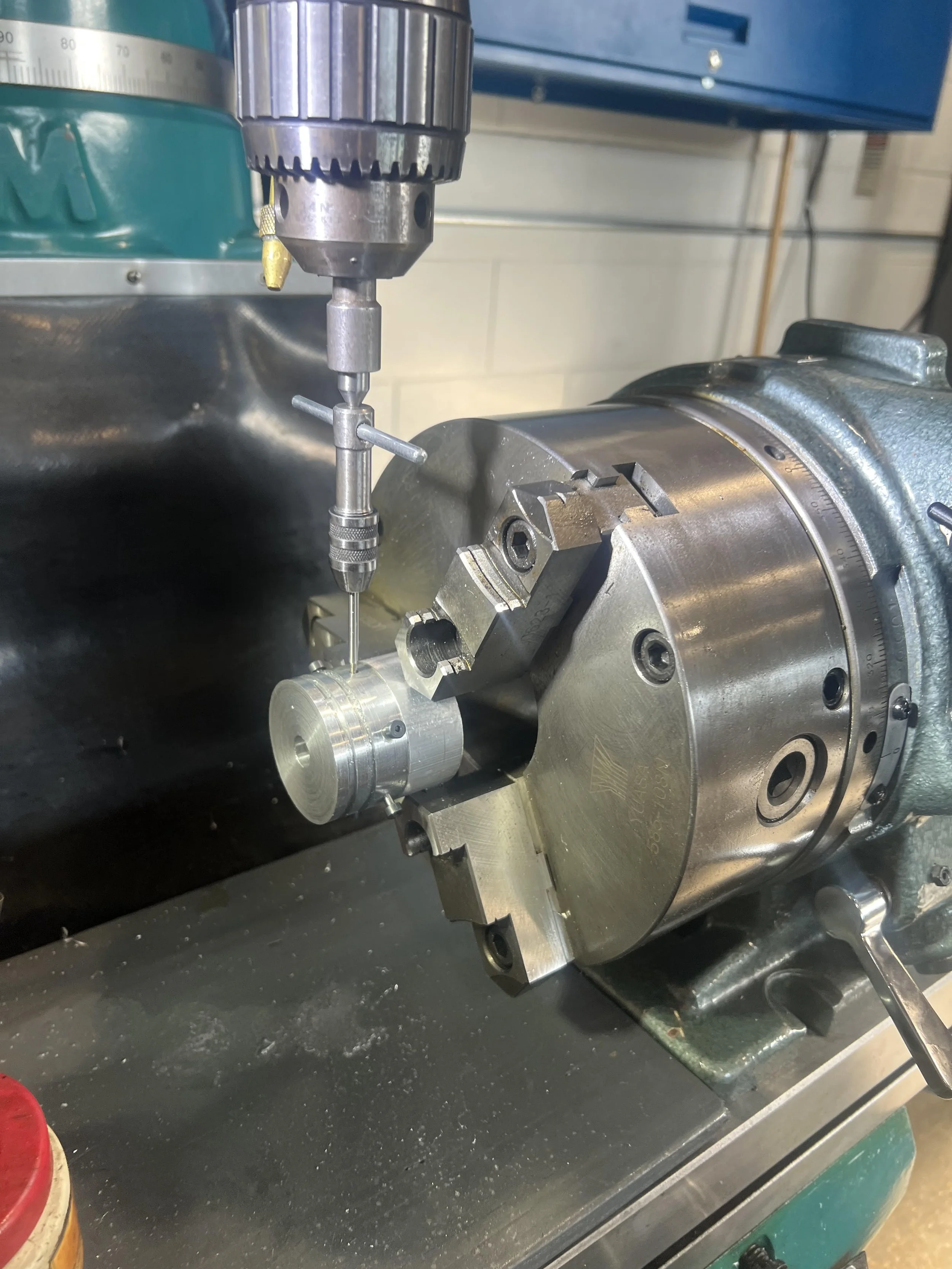

In my senior year of college, I took it upon myself to dive into rocket propulsion and engine design—something we didn’t cover much in class. After a lot of late nights and digging through textbooks and research papers, I put together a small team of four and we set out to design a hybrid rocket engine from the ground up. I led the effort across system design, component modeling, and building out a custom data acquisition setup to support static fire testing. Once the design was solid, I started machining the engine parts by hand using manual tools in our shop. It was a hands-on, ground-up project that blended theory, teamwork, and fabrication—exactly the kind of challenge I love.

Performed trade studies to select propellant and engine configurations while minimizing engine mass and costs.

Led 4 person team to keep project timeline on track as well as steer the team towards the right direction.

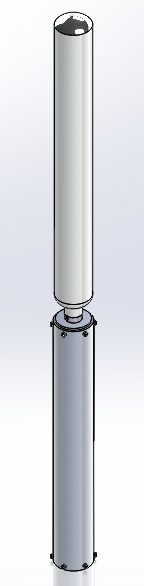

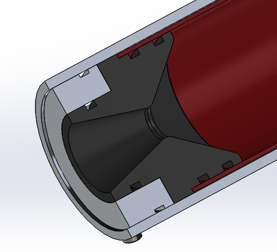

Designed combustion chamber, injector bulkhead, nozzle, and nozzle retaining ring.

Conducted hand calculations to ensure a minimum factor of safety of 2 is found in the combustion chamber and all bolted connections during firing.

Began machining of combustion chamber and injector bulkhead,

Delivered engineering drawing with specifications to local machine shop for graphite nozzle.

Engine Specifications

Oxidizer: Nitrous Oxide

Fuel: High-Density Polyethylene

Thrust: 112 lbf

Oxidizer to Fuel Ratio: 6.5

Combustion Chamber Pressure: 500 psi

Mass flow rate: 0.4585 lb/s

Dry weight: 5.60 lbs

Diameter: 2.25 in

Height: 36.15 in