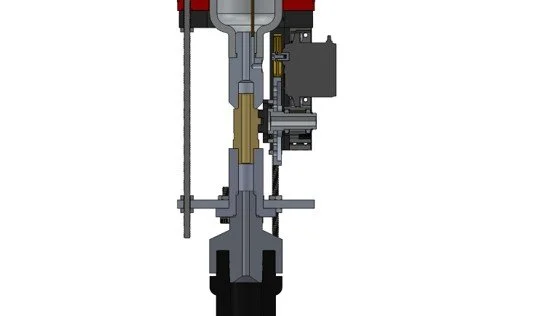

Throttling Hybrid Rocket Engine

For my senior design project, I led a team of four to modify a commercial off-the-shelf hybrid rocket engine to achieve throttleable thrust. This was accomplished by integrating a servo-actuated ball valve between the oxidizer tank and combustion chamber to precisely meter oxidizer flow based on real-time load cell feedback. I designed, analyzed, and machined all custom components, while also managing task assignments, schedules, and a strict $1,000 budget. To characterize the system, I conducted a mass flow experiment using CO₂ as a surrogate fluid, providing valuable data on the ball valve’s performance.

Modified a commercial of the shelf hybrid engine to throttle the mass flow rate of nitrous oxide

Designed custom components using SOLIDWORKS

Performed stress analysis on metallic circular plates to verify safety factor

Machined all metallic parts on manual mill and lathe

Wrote Arduino code to actuate ball valve motor based on load cell feed back

Characterized ball valve performance by designing and executing mass flow rate experiments using CO₂ as a surrogate oxidizer